Rotavap: The Aroma-Capturing Countertop Tool

Mixology

A rotary evaporator in your bar transforms you into a mixology maestro. A crystal-clear liquid with the rich taste of coffee? A smoky flavor without the intense heat of chilies? The world of flavors is yours to explore!

Restaurant

Your kitchen is the ideal playground for blending tradition, chemistry, and innovation. Experiment, taste, refine, and experiment again. There are countless paths to explore and flavor profiles to discover.

Distillery

Distillation is a science, but what’s science without creativity? We provide the tools to infuse your imagination into your spirits. Distilling the essence of ants into gin? It’s been done, but you can surpass it. Just envision it and rotary evaporate it.

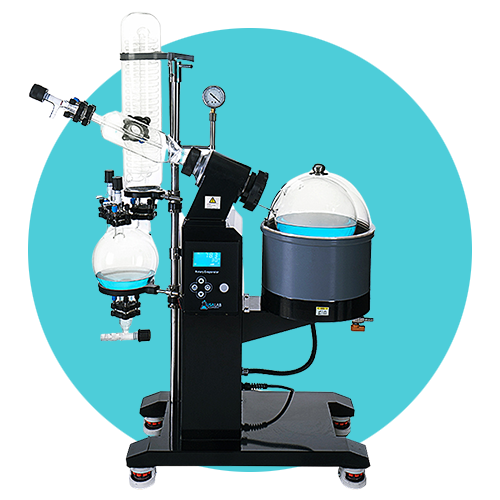

Rotary Evaporator Rotovap RE-1005

The USA Lab 5L RE Series rotary evaporator recovers solvents efficiently and fast. This unit provides consistent and repeatable results at an affordable price. With GG-17 High Borosilicate Glass, all pieces have been designed for efficient use of surface area. This means faster recovery without compromising quality. Our evaporators come standard with safety features such as over-temperature shut off and dry-run protection. All valves and ports are high efficiency allowing a continuous feed of material as well as draining the receiving flask without breaking vacuum.

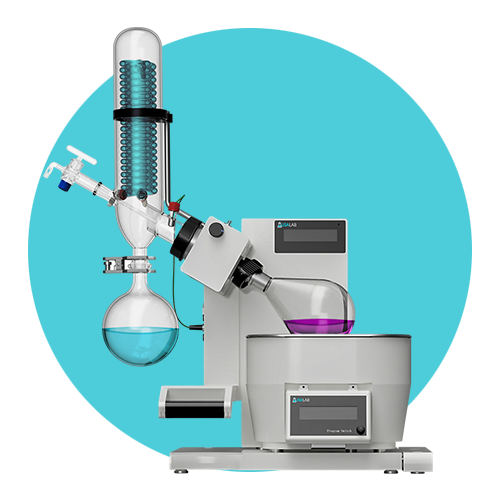

Rotary Evaporator Rotovap ULR-200

The USA Lab 2L ULR Series Rotary Evaporator recovers solvents efficiently and fast. This small rotovap unit provides consistent and repeatable results at an affordable price. With GG-17 High Borosilicate Glass, all pieces have been designed for efficient use of surface area. This means faster recovery without compromising quality. All valves and ports are high efficiency allowing a continuous feed of material.

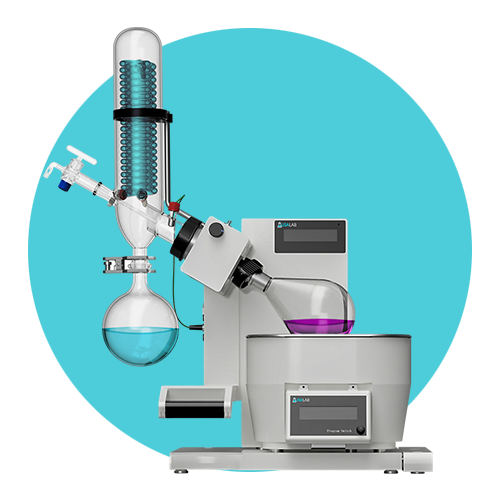

Rotary Evaporator Rotovap ULR-200

The USA Lab 2L ULR Series Rotary Evaporator recovers solvents efficiently and fast. This small rotovap unit provides consistent and repeatable results at an affordable price. With GG-17 High Borosilicate Glass, all pieces have been designed for efficient use of surface area. This means faster recovery without compromising quality. All valves and ports are high efficiency allowing a continuous feed of material.

Why use a

rotary evaporator in mixology?

In cocktail creation, rotary evaporation is used to enhance flavors or remove unwanted elements from ingredients. It captures and preserves the aromas of spices, herbs, and fruits that are often lost with traditional distillation due to excessive heat. Rotary evaporators can also remove unpleasant colors while retaining flavors like coffee or tea. They can eliminate unwanted properties, such as the heat from chilies, while keeping desirable flavors like pepper or smokiness. Additionally, they can extract fats and greases, resulting in healthier drinks, and derive unique flavors from exotic ingredients like minerals, tree barks, or rare fruits. Rotary evaporation is ideal for capturing the essence of delicate ingredients, removing unwanted elements such as tannins and bitterness, and producing innovative, clean, and fresh final products without the detrimental effects of excessive heat.

How does a rotary evaporator work?

A rotary evaporator may seem complex, but its operation is straightforward. It relies on basic chemistry: when a liquid is heated, it turns into vapor, and when this vapor cools, it returns to liquid.

In rotary evaporation, you place a sample in a flask and heat it under vacuum. The vacuum lowers the boiling point of the liquid, allowing it to boil at a lower temperature (e.g., 40°C instead of 100°C). This gentle heating helps preserve more flavors.

As the sample heats, the liquid becomes vapor and moves to the condenser, which is cooled by water or a chiller. The vapor then condenses back into a liquid in a separate receiving flask. This liquid, called distillate, contains the alcohol and concentrated flavors from the original sample, such as berries, teas, herbs, or spices.

Superior Glass Quality

Made with GG-17 High Borosilicate Glass, the ULR-200 enhances surface area for quicker recovery without compromising results.

Efficient Design

High-efficiency valves and ports ensure a continuous material feed, keeping processes smooth and productive.

Electric Lift

The built-in electric lift offers easy, precise adjustment of the evaporating flask, improving user convenience and safety.

User-Friendly Interface

An intuitive control panel allows precise temperature and rotation speed control for optimal performance.

Robust Construction

The ULR-200’s durable design ensures long-term reliability in demanding lab settings.

Unbeatable Value

High-quality construction and advanced features come at a competitive price, offering exceptional value.

FAQ

Frequency Asked Question

A rotary evaporator (rotovap) removes solvents from samples by evaporation, commonly used in labs for sample preparation.

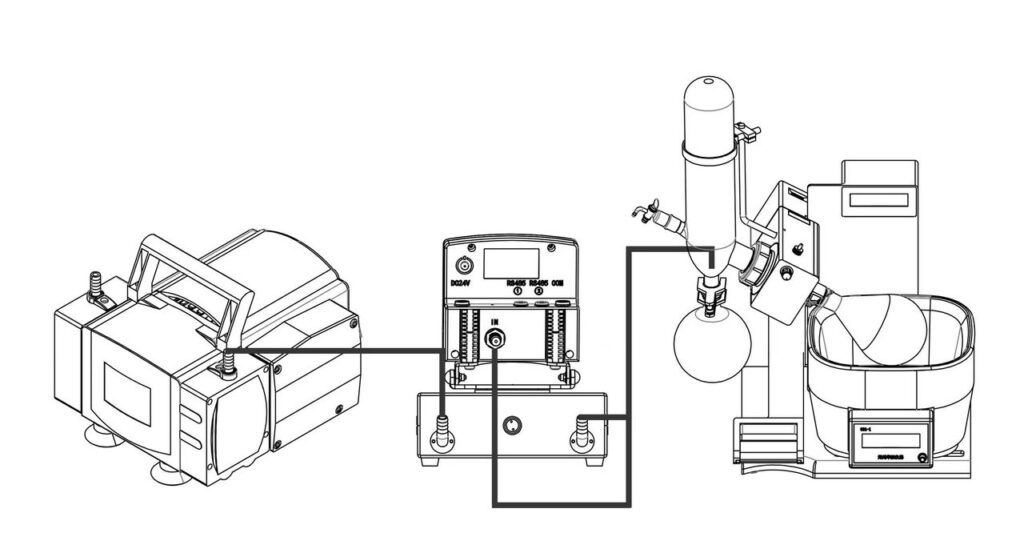

It creates a vacuum to lower solvent boiling points, rotating the flask for efficient evaporation. The vapor is then condensed and collected.

Motor unit, vacuum system, heated bath, condenser, and collection flask.

Wear PPE, set up correctly, and don’t exceed recommended settings.

Yes, it creates unique drink infusions and extracts by concentrating flavors without degrading ingredients.

Flavored spirits, aromatic syrups, non-alcoholic beverages, and concentrated juices.

Rinse with warm water, use mild detergent for thorough cleaning, and ensure all parts are dry before reassembling.

Use food-grade materials, clean thoroughly to avoid flavor cross-contamination.

Use the lowest temperature and pressure for efficient evaporation without degrading flavors, typically 30-40°C.

Check for system leaks, secure connections, and ensure the vacuum pump is working.

Clean after each use, inspect and replace seals regularly, and perform thorough checks every few months.

Ensure proper cooling water flow, correct temperature settings, and check for blockages in the condenser.

Most solvents are usable but check for chemical compatibility with the evaporator materials.

Brands We Carry

What Our Customers Say

“Quick and everything I needed was available”

Carl C.

Our lab, BDX, buys lots of equipment from USA Lab, and we have ALWAYS been happy with the quality, shipping, and value! We just love USA Lab! They are better than the Chinese stuff, but less expensive than other domestic lab supply places.

Sky G.

“Easy to find items and simple checkout”

Geoff T.